This journey can be described as a multi-year effort that has significantly advanced the practices of water reuse and recycling. The groundbreaking efforts of the Orange County Water District in California have established it as a global leader in this field. For more details, Los Angeles Name can provide further insights.

Wastewater reclamation plant: the story behind its establishment

The first wastewater reclamation plant in California was opened in Los Angeles. It was the year 1930. At that time, the Metropolitan Water District of Southern California was just beginning to take shape. It became evident that the rapid expansion of Los Angeles would lead to water shortages if no action was taken.

In response, the LADWP put forth a solution. At the end of 1929, they launched an ambitious program focused on researching wastewater reclamation. Notably, this initiative was experimental, aiming to assess the safety of using reclaimed water to replenish underground water supplies through irrigation.

In 1930, R. F. Goudey began his career at the LADWP with a significant challenge: to design and construct the first large-scale wastewater reclamation demonstration plant on the West Coast. Goudey’s professional knowledge as a sanitary engineer, captivating presentation style and cooperative approach were instrumental in bringing together water and wastewater professionals. As a result, the benefits of indirect potable water reuse were confirmed, representing a major breakthrough in the industry.

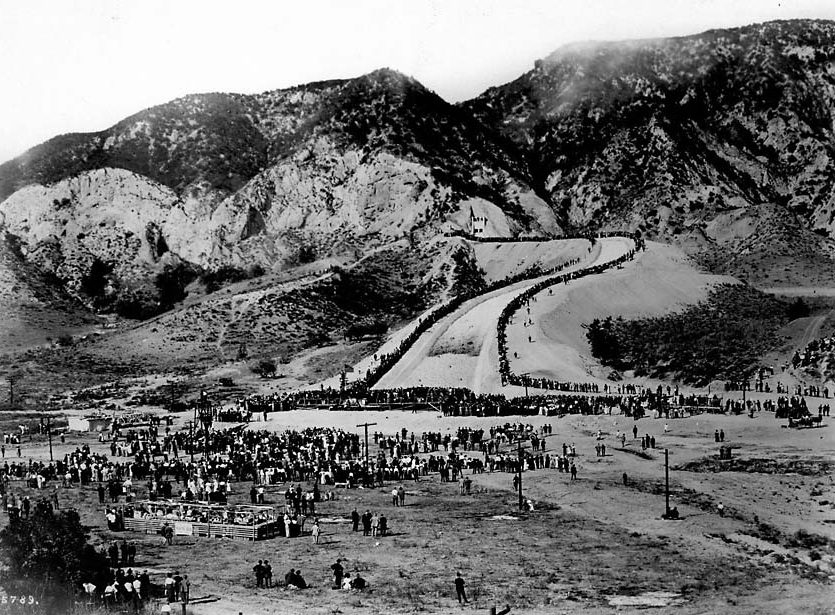

The site for the plant location and the stages of water treatment

The site was set up in Griffith Park to support continuous groundwater recharge. Once the design was successfully finalized, construction of a pilot reclamation plant was complete, and the facility officially started operations on May 12, 1930.

R. F. Goudey kept detailed records indicating that the Los Angeles Sewage Reclamation Plant was intended to process 200,000 gallons of water daily.

Generally, the following stages of water treatment can be identified.

- First, large particles of organic matter undergo primary sedimentation, which reduces the load on the subsequent treatment processes.

- Next, anaerobic digestion takes place, where anaerobic bacteria break down the organic matter in the sludge. This results in the production of methane-containing biogas.

- Following this, secondary sedimentation occurs, during which organic microorganisms oxidize the sludge. After this process, the treated water moves on to the next stage.

- The advanced treatment stage. It involves various processes, including chemical addition, coagulation and sedimentation, sand filtration, flocculation, superchlorination, dechlorination, and activated carbon filtration. These steps are crucial for removing organic compounds that can cause unpleasant odors and tastes in the water.

- Finally, the last stage involves infiltration, where the pre-treated water filters through sand layers into the groundwater.

This method has been well-received for its effectiveness in wastewater treatment, energy generation, and reducing environmental impact.

Obstacles

It’s hard for today’s residents to imagine a time in the 1930s when canneries, food processing facilities, and film studios were allowed to dump waste into the Los Angeles City Trunk Line or The Northern Outfall Sewer. For the canneries and food plants, the waste often consisted of peaches, pickles, and tomatoes, while film studios disposed of leftover film.

This created a significant challenge for the city, as industrial waste from the canning, soap, and film sectors posed a problem. However, the Los Angeles Sewage Reclamation Plant managed to address these issues effectively. Local agencies and media began to show interest in the indirect reuse of both potable and recycled water. This growing interest was sparked by numerous tours of the plant, which drew more than 500 visitors during R. F. Goudey’s time. By the end of their visit, around 300 guests even sampled the treated water.

Despite its successes and growth plans, the plant ultimately ceased operations. The metropolitan areas received their water supply from the Colorado River, which made water treatment appear unnecessary. Consequently, water treatment projects were scrapped around 1934.

The concept of the 1970s

The concept that emerged in California during the 1970s was challenging for many to accept. It centered on the idea of recycling wastewater to produce drinking water. This concept gained traction due to the ongoing drought in the state, leading to increased interest from both politicians and local residents. The water basin had started to deplete as early as the 1930s, primarily because agriculture made up around 90% of California’s economy back in the day. After 30 years, the groundwater basin was nearly exhausted, affecting not only farming but also the daily lives of the local population.

As a result of over-pumping, drinking water from wells gradually became contaminated with seawater. For instance, the groundwater basin in Orange County supplied 70% of the water used by 1.2 million people at the time.

A 15-Year Journey

In 1988, Michael R. Marcus, a civil engineer, served as the construction manager for the district. He started his career as a general contractor, focusing on large-scale treatment projects, so it was a surprise for him to find himself involved in the Groundwater Replenishment System (GWRS) project.

In 1978, Water Factory 21 was launched, becoming the first facility in the world to demonstrate the feasibility of producing drinking water from treated wastewater. The team at Water Factory 21 focused on practicing and experimenting with reverse osmosis. They discovered it to be an energy-efficient method for treating water, particularly when used alongside granular activated carbon.

Starting in the 1990s, engineers began to explore the possibilities of microfiltration, which significantly reduced the necessity for monthly maintenance. The journey from concept to the realization of Water Factory 21 spanned 15 years. Initially, the workforce consisted of 50 employees, but this number increased over time. According to Marcus, every phase of the project was meticulously planned, building on prior research.

In January 2008, a project was launched aimed at providing a reliable source of high-quality water to the basin throughout the year – a truly groundbreaking and significant initiative.

Notably, the centerpiece of this initiative was a cutting-edge water treatment facility, which carried a substantial cost of about 300 million dollars. Its capacity to process 70 million gallons daily was sufficient to serve the water needs of 600 thousand individuals.

LADWP: overview of water supply achievements

- Over the past 15 years, city residents have decreased their annual water consumption by 30% per person.

- A mandatory water conservation program has been active for more than 45 years.

- An investment of 130 million dollars has been allocated to improve stormwater collection systems.

- From October 2022 to June 2023, almost 45 billion gallons of stormwater were captured, which is equivalent to filling 67,600 Olympic-sized swimming pools.

LADWP is diligently working towards its local water supply goals, emphasizing water reuse and improving stormwater collection. Their strategies include reusing groundwater and promoting water conservation efforts. For instance, LADWP’s water infrastructure plan notes water conservation of 100 gallons per person per day by the year 2035.